Schumer work clothes

- Category: پیشفرض

Description

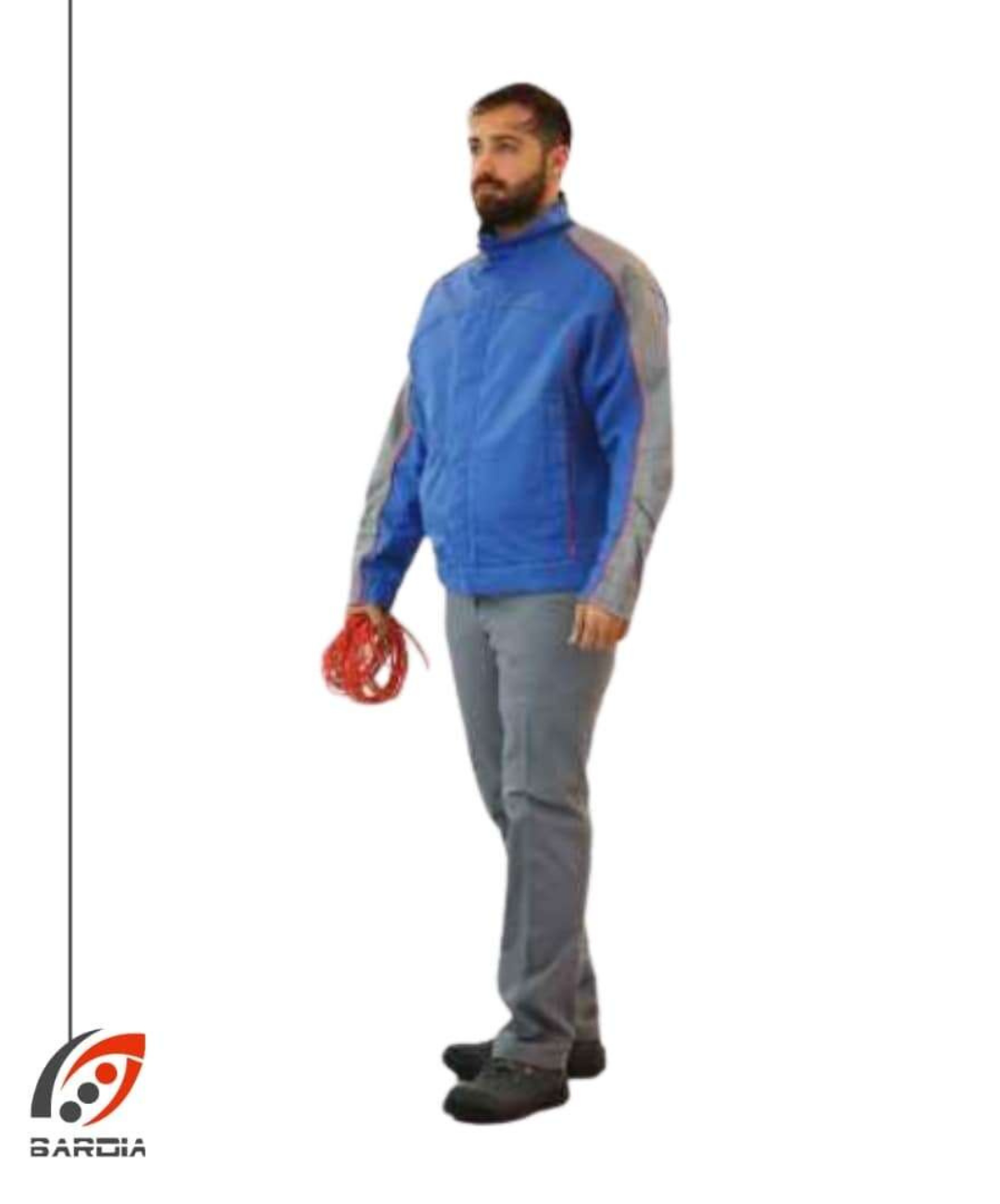

Bardia Flame-Retardant Workwear (Shumer)

Bardia Flame-Retardant Workwear is resistant to molten steel and adheres to standards such as EN530, EN470-1, EN533+40*90c, and ISO5797. This clothing is manufactured by Bardia Jonoub Textile Company using two types of flame-retardant fabrics: B84 and B86. Unlike fake and counterfeit samples, this garment is guaranteed by the company to withstand up to 50 industrial washes. To verify the authenticity and integrity of the product, you can request an import declaration and documentation for the fabric from Bardia store experts.

Jacket Features:

- Sleeves and Cuffs: Cuffs have Velcro for adjustment.

- Upper Pocket: One pocket on the left chest or a flap pocket with a button.

- Mobile Pocket: One internal pocket on the left side of the jacket.

- Lower Pockets: Two pockets or flap pockets with four-piece buttons.

- Placket: Four-piece buttons and Velcro.

Trouser Features:

- Waist: Elastic waistband.

- Placket: Button closure.

- Front Pockets: Two patch pockets.

- Back Pocket: One pocket on the right side.

- Composition: 100% Cotton.

- Sizes: S to 4XL.

- Usage Location: Steel and alloy companies.

Due to the sale of similar counterfeit products in the market, we hereby declare that if you purchase this product from a producer or store other than Bardia, you must ensure the authenticity and quality of the product. To test the garment, dress a hypothetical mannequin and place a plastic or polymer sheet underneath the garment that is sensitive to molten heat. Additionally, for further assurance, always wash the garment before use and refer to guidelines on how to distinguish genuine from counterfeit Shumer workwear.

What is Flame-Retardant Workwear?

Flame-Retardant Workwear is a type of industrial clothing designed to acquire flame-resistant and fire-retardant properties. This is achieved either through the use of inherently heat-resistant fibers (such as Nomex, Kevlar, and Pynex) or by applying special chemical treatments to ordinary fibers. This characteristic means that if the garment comes into contact with a flame, it will not ignite quickly, will not spread the flame, and will self-extinguish. The primary goal of this protective clothing is to provide sufficient time for the individual to escape from a hazardous area or reduce the severity of burns.

Key Considerations for Purchasing Bardia Textile's Shumer Workwear:

When purchasing flame-retardant workwear, paying attention to a few key points is essential to ensure you get the best flame-retardant workwear suited to your needs:

- Type of Activity and Level of Risk: The required fabric and level of protection vary based on the industry and the extent of exposure to flame and heat. For instance, flame-retardant welding workwear must offer higher resistance to sparks.

- Standards and Certifications: Ensure that the garment has valid international certifications such as EN ISO 11612 (protection against heat and flame) and EN ISO 11611 (protective clothing for welding).

- Material and Composition: Various types of flame-retardant fabrics are available. Nomex workwear and Kevlar workwear are among the top choices, offering inherently high resistance.

- Comfort and Ergonomics: In addition to protection, the garment must be comfortable and allow the user freedom of movement.

- Brand and Manufacturer's Reputation: Reputable manufacturers of flame-retardant workwear provide high-quality and reliable products.

Price of Shumer Workwear and Influencing Factors:

To inquire about the current price of flame-retardant workwear and compare the prices of various types of fire-resistant workwear, it is recommended to contact sales experts at PPE supplier companies or refer to the safety workwear price lists on specialized websites.

The Necessity of Using Flame-Retardant Workwear:

The use of industrial flame-retardant workwear in high-risk environments is a vital necessity for preserving the lives and health of employees. The main reasons for using this safety clothing include:

- Protection Against Fire and Burns: The primary reason is a significant reduction in the risk of severe burns and fatalities resulting from fires in the workplace.

- Increased Employee Safety: By wearing fire-resistant workwear, employees can work with greater confidence in hazardous environments, which also helps increase productivity and reduce occupational stress.

- Compliance with Safety Standards and Regulations: Many industries (oil and gas, petrochemicals, welding, metallurgy, and firefighting) are required to comply with specific personal protective equipment standards that mandate the use of heat-resistant workwear.

-

Prevention of Medical Costs and Financial Losses: A reduction in accidents and burns directly leads to lower medical costs, compensation, and losses due to production shutdowns.

Write a Comment